Plants and Laboratories

Undertaking construction projects for plants and laboratories requires thoroughgoing knowledge regarding construction itself as well as MEP equipment and other production-related facilities. Our staff and engineers have extensive experience in plant and laboratory projects including new building projects, refurbishment, and reorganization following mergers, and make use of this experience to help customers successfully complete their projects.

Plant construction brings with it demand for production efficiency enhancements, flexible planning, and schedule management to make sure plants are operational in time to meet production schedules. In addition, existing production facilities need a complex counter measure of problems that must be addressed, including earthquake-proofing, business continuity planning (BCP), equipment deterioration over time and legal compliance issues. At Meiho Facility Works, we offer Meiho PM services and we work together with customers to overcome problems throughout the project as a whole.

When it comes to laboratories, demand for R&D that achieves greater innovation as well as work styles that promote such R&D are on the rise. We make use of highly specialized knowledge on such laboratories while also relying on a rich array of office-building experience (which includes effective work style proposals) as part of support efforts to make customers' ideal laboratories a reality

Major Projects

Plants

Plants Project Records

| Client | Project Summary | Location | Project Scale |

| JX Metals Precision Technology Co., Ltd. | Automotive parts plants Construction Project | Shizuoka | Approx. 29,000m² |

| Tyco Electronics Japan G.K. | Automotive parts plants Construction Project | Shizuoka | Approx. 24,000m² |

| Food product manufacturer | Food plant Refurbishment project | Hyogo | Approx. 8,000m² |

| Printing company | Printing factory Construction project | Saitama | Approx. 5,500m² |

| Mitsubishi Shoji Foodtech Co., Ltd. | Food plant Conversion project | Saitama | Approx. 5,000m² |

| Precision instrument manufacturer | Construction Project for Head Office Factory | Tokyo | Approx. 3,000m² |

| Osaka Prefecture University | R&D Center for the Plant Factory Construction Project | Osaka | Approx. 1,300m² |

| Tokai Carbon Co., Ltd. | Post-earthquake recovery project for Ishinomaki factory (2 new buildings) | Miyagi | Approx. 1,300m² |

| Chemical product manufacturer | Pharmaceutical plant New-facility construction project (underway) | ― | ― |

| Chemical product manufacturer | Chemical product plant BCP measures project | Aichi | 5 bldgs. |

| Food product manufacturer | Food plant Seismic strengthening project | Shizuoka | 15 bldgs. |

Laboratories

Laboratories Project Records

| Client | Project Summary | Location | Project Scale |

| Chemical manufacturer | Laboratory and office building Construction project (underway) | Hyogo | Approx. 5,300m² |

| Osaka Prefecture University | Research Center for BNCT New-facility construction project | Osaka | Approx. 1,800m² |

| Technology Research Institute of Osaka Prefecture | Renewal of heat source equipment and air condition equipment | Osaka | Approx. 37,000m² |

Services

- Project management for a new building, renovation, and consolidation and relocation

- Basic concept for a new building, renovation, and consolidation and relocation (Support for project launch)

- Support for BCP and environmental measures

- GMP/GLP Measures and Validation Support

- Relocation Management Services for Laboratory and Other Equipment

[Plants and Laboratories] Project management for a new building, renovation, and consolidation and relocation

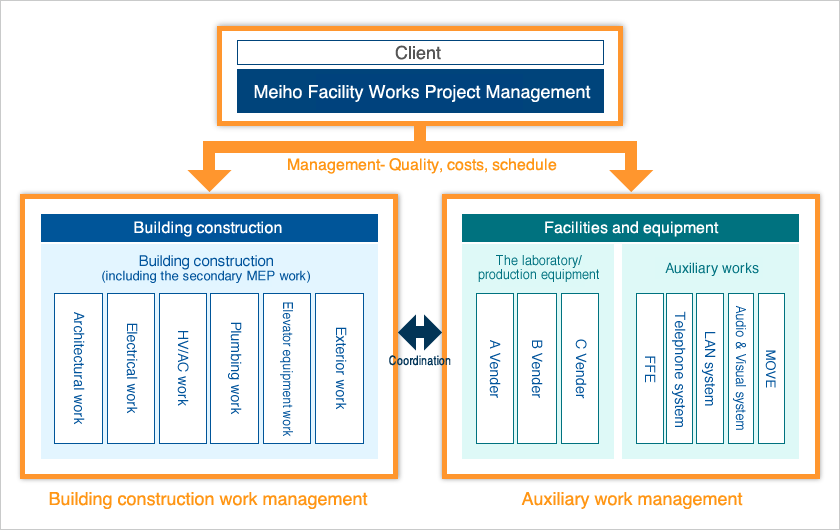

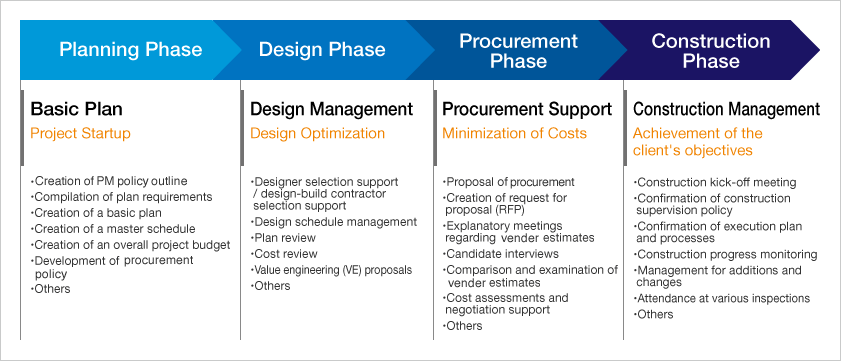

For a new building, renovation, and consolidation and relocation of plants and laboratories, our engineers, who are familiar with production facilities and laboratories, implement client oriented project management without relying on certain dedicated contractors. We provide one stop service for everything from the establishment of a basic concept and basic plan to the management of design, procurement actual construction, relocation of production facilities, and management of furniture and fixtures, ICT, etc.

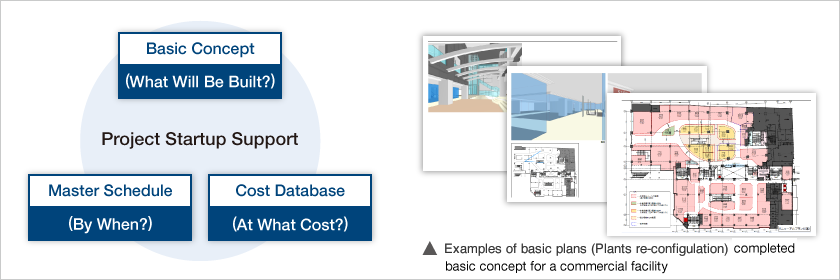

[Plants and Laboratories] Basic concept for a new building, renovation, and consolidation and

relocation (Support for project launch)

Our engineers, who have extensive experience in plants and laboratories, organize challenges and requirements with the project teams on the customer side from conceptual stages, envision the framework that the facilities should possess, and support the customers to develop their basic plans. We support the project startup by clarifying "what," "how", "how much," and by "when" it should be done through plan adjustments with the production lines and logistics, review of construction steps considering the operational continuity of the plants, and development of the master schedules along with production operation, precise budgeting, etc.

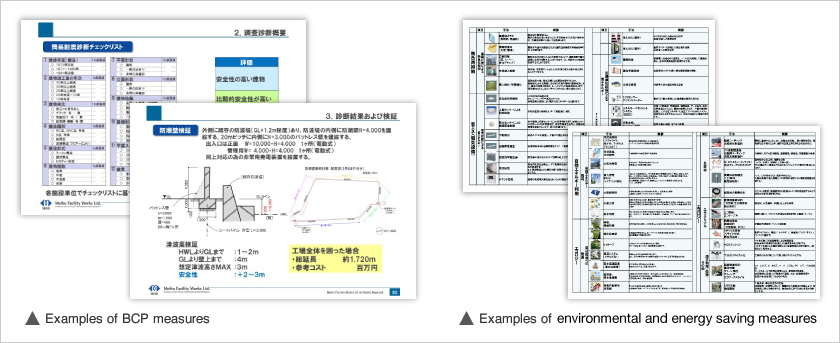

[Plants and Laboratories] Support for BCP and environmental measures

For a plant or laboratory, it is important to ensure business continuity and safety in case of a disaster. We support the development of various BCPs (Business Continuity Plans) such as secondary materials for a building, ceiling, seismic strengthening of production facilities, and hazard countermeasures for important facilities against tsunami, flooding, etc., according to the importance and risk values.

Also, as environmental consideration and energy saving are being more focused, the plants with high energy consumption are required to take more advanced initiatives. For those challenges, we deliver optimal solutions leveraging the latest technologies.

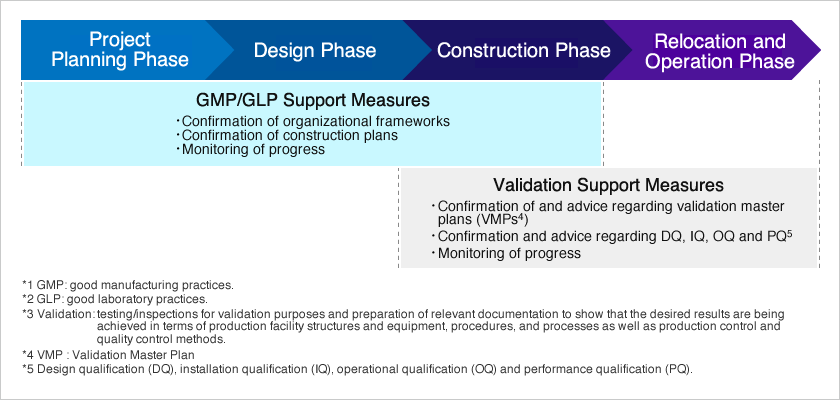

[Plants and Laboratories] GMP/GLP Measures and Validation Support

As GMP1 and GLP2 continue to become global standards for plants and laboratories everywhere, demand for the establishment of quality control systems is also on the rise. Our staff and engineers possess specialized knowledge on GMP- and GLP-compliant facilities, and make use of this knowledge throughout all stages of facility construction project including planning, design and actual construction to assist in the creation of facilities optimized to achieve high-level quality assurance for products and experiments/testing. This support extends all the way through to validation3 to help customers smoothly get their facilities up and running.

- *1 GMP: good manufacturing practices.

- *2 GLP: good laboratory practices.

- *3 Validation: testing/inspections for validation purposes and preparation of relevant documentation to show that the desired results are being achieved in terms of production facility structures and equipment, procedures, and processes as well as production control and quality control methods.

- *4 VMP : Validation Master Plan

- *5 Design qualification (DQ), installation qualification (IQ), operational qualification (OQ) and performance qualification (PQ).

[Plants and Laboratories] Relocation Management Services for Laboratory and Other Equipment

When it comes to plants and laboratories, customer needs can only be fully met once the facilities as well as the laboratory/production equipment that make up the core of such facilities have been confirmed as firmly and reliably operational. We provide one stop services for construction and installation management covering everything from production/laboratory equipment installation and relocation to office-function installation and ancillary construction work. Our total management services include support for the selection of optimal designers and contractors, relocation schedule management that doesn't interfere with facility operations, and various other construction-related requirements leading up to successful operational start-up of customer facilities.